Hydraulic hose crimper industry development

Video : How To Use Hydraulic Hose Crimping Machine

September 5, 2017

Hydraulic hose crimping machine export procedure

October 30, 2019Hydraulic hose crimper industry development

Early at 1795, Joseph Bramah patented the hydraulic press. After years, this technology has made progress. And Harry Franklin Vickers was called the “Father of Industrial Hydraulics” .

As Pascal’s Law states that at any point in the in-compressible fluid that is subjected to pressure increases by external forces, this pressure gain is instantaneously transmitted to each point of the stationary fluid in all directions.

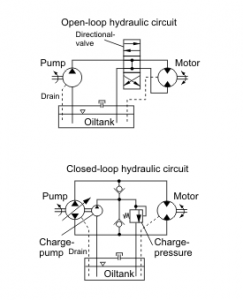

The hydraulic fluid path is called hydraulic circuit,and it is the key of the hydraulic hose crimping machine.the drawing and principle is like below:

With the development of the economy and the construction of infrastructure, various construction machinery and hydraulic machinery, mining machinery, like trucks, excavators, and lifts are needed in the project.

The hydraulic technology provides kinetic energy in the whole machine, and the hydraulic hose is like the blood vessel that transports fluid as blood of machine. The joint, the connection of hose and fittings of the engineering machinery will break in thousands of operations, resulting in oil leakage and loose power.

Mechanical shutdown affect the work and the whole project. The crimping machine allows the mechanical blood to re-flow, which can improve work efficiency and escort the operation of the project. The crimping machine is mainly used for maintenance. Also some shops will use the crimping machine to press and crimp kinds of hoses with quantity to sell the Hose assembly.

Hose crimping machine is operated by a motor to convert electrical energy into kinetic energy in the hydraulic circuit. And push the fluid to complete the crimping process.

After decades of development, hose crimping machine has already had relatively mature technology and experience.

The crimping machine is suitable for all kinds of mechanical high and low pressure oil pipes, gas pipes, water pipes, cable joints, automobile air conditioning pipes, automobile power steering pipes, oil pipes, gasoline fuel supply pipes, as well as the buckles of construction parts and daily hot water pipes. Vehicles, engineering machinery, hydraulic machinery, welding and cutting equipment and other industries.

Our company has been in hydraulic filed for more than 20 years, also has been done export for 10 years.

We really have a long way on our company development.

We would like to introduce our boss. Long long ago, he had a repair shop to repair sprayer hose and hydraulic valve. And he found at that time there were a big market on crimping machine request. So he tried to start to study and try to produce this kind of machine.

At the beginning, only five teammates to solve everything. And future prove that he is right and the need of hydraulic crimper increase largely from that time. As our company senior employee said, the customers were waiting the production finished, as soon as our crimper installed and checked there is no problem, customers would pay and drive it to their shop immediately.

And with more and more customer trust and market support, we have a bigger workshop and more and more workers and sales, and we have a factory later, after all we have another new bigger factory. We would like to thanks to our customers and distributors. Even we have problems at the beginning, they choose to trust and choose us. So when our company grow up, we will support all life time technical support to all our customers, it is time that we support you.

Except to our factory scale, our technology has improved year by year. At the beginning, our factory could only provide with one type model to our domestic market. As we well know, the crimper will have oil leak and insufficient crimping force, also dies broken. Our customer feedback to us and our boss lead the technology team to overcome all kinds of difficulties in all filed.

At the beginning, the failure rate of hose crimper is about 10%, and comparing now, our crimper failure rate is only 1%, we believe it is a good job and we will do our best to offer more good quality machine. At the beginning, our crimper only could crimp hoses, refer to the precision, more or less is the standard at that time. And customer could bear that.

When we do exporting, we find there are many customers have a very serious demands on precision after crimping, so we begin to improve all our spare components like micrometer and valve and technology to reach customer request.

When we do exporting, we find there are many customers have a very serious demands on precision after crimping, so we begin to improve all our spare components like micrometer and valve and technology to reach customer request.

Now our precision could reach 0.01mm, better now. And the beginning, we use all domestic components and some times the crimping force is not powerful when it meets huge hoses, like 2 inch 4sh hoses, and now rexroth valve and Italy pump has been chosen and it shows a durable and powerful superior performance. Also Siemens motor is also available.

At the beginning, we could only crimp regular hoses and small hoses, now we could crimp almost any type of hydraulic hoses, any size dies could be customized, except hose dies, we could crimp square and round steel pipes, and even hexagon tube could be done. Wire rope and cable are no problem at all.

Now we are confident to say any request on our filed, we will offer you a satisfied offer and machine. We have faith because we have a professional technical team to support us and we have factory to guarantee the production and quality. And our company is professional in hydraulic technology and keep moving forward to improve our technology to satisfy our customer request.

Our products offer customer good machine and also our distributor and end-user offer us advice to improve details and components. Clients also offer us information and request that makes us help each other and build a deep cooperation and contact.

For now, our series is as below:portable model:(including smaller manual hose crimping machine and portable DC12/24V hose crimping machine); service model(also known as repair model):with 220V and 380v as normal model P32 hose crimping machine(any volt and hertz could be customized). Production model:it is for production and it is suitable for production for hose assembly. Also we customize many kinds of crimping machine as customer request: air suspension crimping machine (max opening 170mm); cable crimping machine; side feed crimping machine; huge oil tube crimping machine(6 inch); air condition hose crimping machine;spare steel tube crimping machine.

If you need any kind of crimper, please feel free to contact me via email. We believe we will be your best choice.